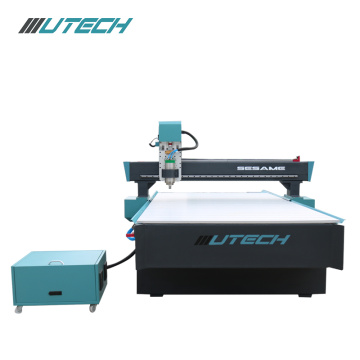

single head equipment for making guitar

Basic Info

Model No.: 1325

Product Description

single head equipment for making guitar

cnc router with Nc-studio control system adopt unique intelligent prediction algorithm, can conveniently check the moving path of tool, and adjust the processing depth of Z axis and the speed of motor.

Make full use of potential capability to achieve high speed processing , curve-linear synchronous with high accuracy. Durable waterproof and dustproof on all XYZ axis. OEM is available as customer`s requirements for machine size and system

Model Sesame

Working Area 1300*2500*180mm

Table structure T-slot table

Transmission Device X, Y axis: Precision helical tooth gear transmission

Z axis: Precision tBI ball screw

Travel speed 0-25000mm/min

Working speed 0-18000mm/min

Driving mode Patent stepper reducer structure

Spindle power 3.2KW water cooled spindle motor

Spindle speed 0-24000rpm

Diameter of cutter φ3.175-φ12.7mm

Command code HPGL G-code

Working voltage AC220V/Hz

Device interface Standard PCI/USB interface optional

Resolution 0.01mm

Machine size(W*D*H) 1935*3015*1500mm

Warranty 12 months

Weight 1000kg

Warm tips: all parts of the machine can be upgraded or changed. Please tell us your material and size. We will customize the most suitable machine for you.

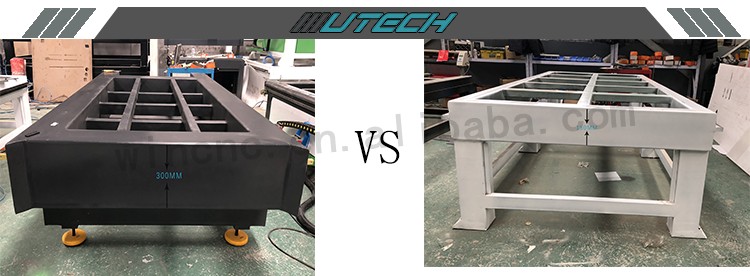

1/ Machine bed with 200*300mm square tube welded together, compared to ordinary machines, we use the square tube model can better reflect the stability of the equipment.

2/ Bed welding process increases the reserved forklift, highlights two major advantages: First, increase the strength of the bed itself; Second, it`s more convenient for customers to disuse the equipment.

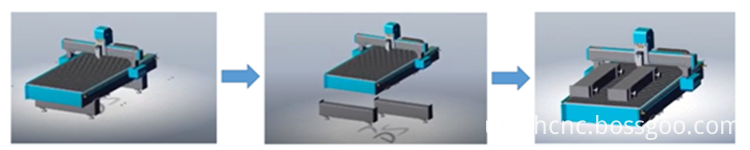

3/ we adopt separated type lathe bed structure. With the purpose of: After ensuring that the customer receives the equipment, there`s no need to make a complete disassembly and will not affect the operation of the equipment. In this circumstance, we optimized the design structure, then, the final packaging size of the product was saved by 5m³.Thus saving transportation costs.

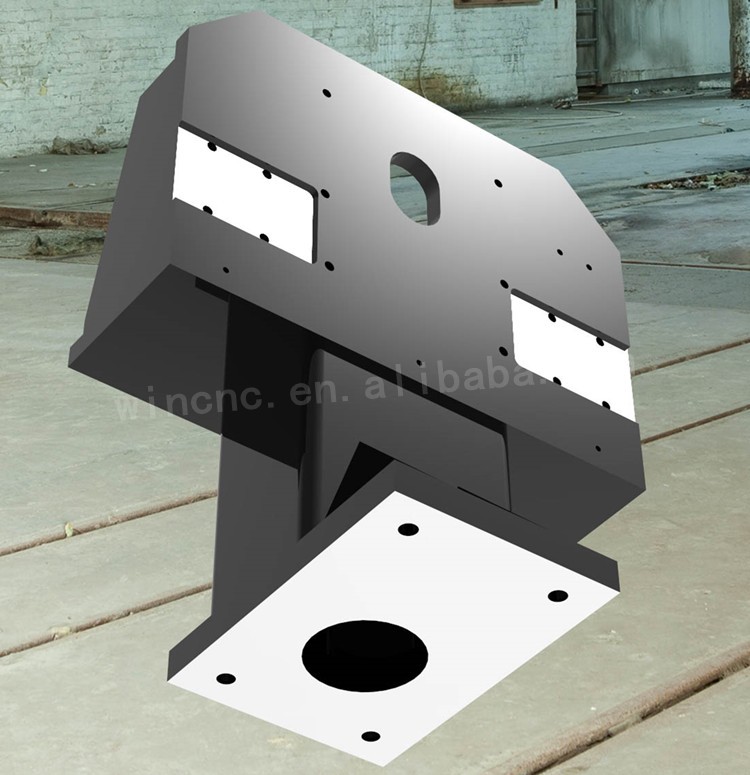

4/ Transmission column, we adopt high - precision machining process, ensure the accuracy of accessories. Like insert cavity position, assembly surface.

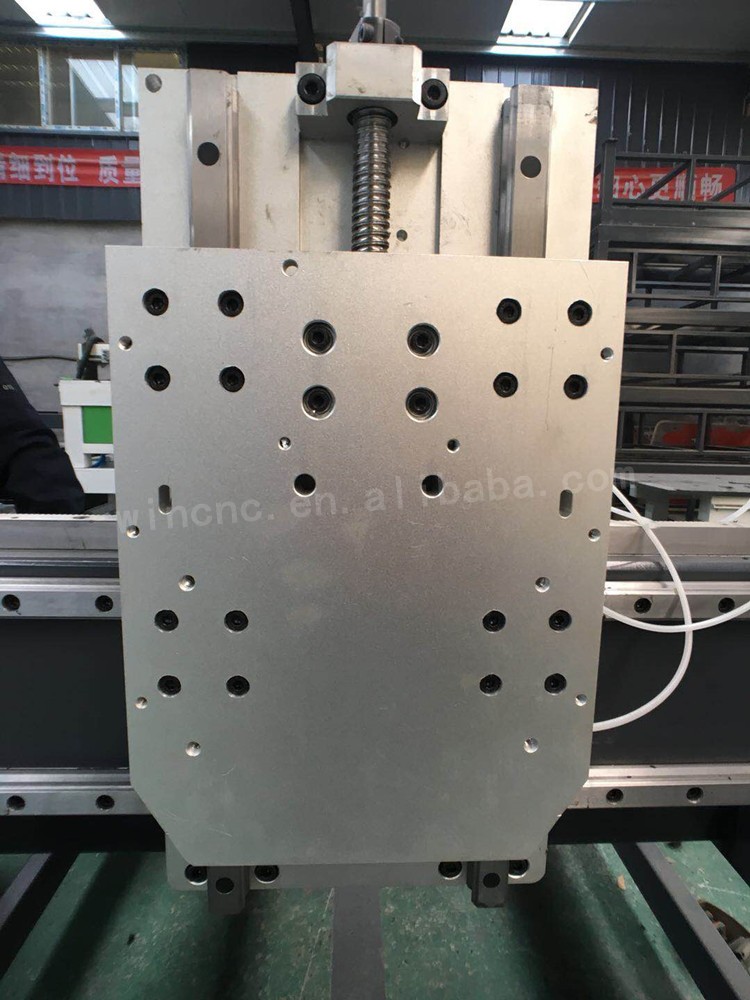

5/ First, For the choice of hand piece, we choose T6061/6063 aviation aluminum alloy as the base material. Through the precision processing of CNC Processing Center, we finished our finished parts. Second, the high requirement assembly process ensures the precision of the product.

6/ Choose heavy duty linear guide rail with high assembly flange sliding block.

7. The High quality SESAME series CNC Router machine comes with 3.2kw water or 3.5 air cooled high frequency spindle. This precision spindle requires no maintenance, uses industry standard ER collects. Fully programmable speeds from 6000 to 24000RPM, and comes complete with pneumatically retractable vacuum hood.

8. The machine main body and the machine legs are freely separable, when delivery the legs are disassembled and put on the table, which will reduce the machine's package size, then will save the shipping cost.

9. Tool box(parameter list/ controller install software/ drawing software/ etc), cutters, etc.

- The bed is welded with thick wall steel tube,Integral thickening square tube, solid and not deformed. After high temperature tempering treatment to ensure the best strength and rigidity.

- The machine head is made of T6061/6030 aluminum parts by professional CNC machining center. After oxidation surface and low temperature annealing treatment, the machine head is lighter and more durable.

- Use 3mm metal sheet for the dust cover,more than ten working procedure, Professional beauty and correction.

- Use Germany ASK 25mm square rails.The Y-axis adopts double-row four-column guide rail, with strong bearing force, fast speed, smooth operation, high precision and high life span.

- Rack adopts German imported high-precision helical rack, which is complementary with the servo motor and professional deceleration device, which runs smoothly, high speed, high precision and low noise..

- Use Simple servo motor, the machine torque is big, processing speed is quick, the highest speed can reach 40m/min.With reducer transmission, the machine is more stable, high efficiency, high precision and low noise.

Shandong U-MAY CNC Technology CO., LTD. Specializes in the research, development, production of CNC MACHINE. Our brand [WIN" has a considerable reputation in the domestic similar products, which has been widely used in wooden furniture, advertising, craft gifts, packaging and printing, logo and etc. Our products have been exported to many countries and regions such as Europe, Russia, Asia, Africa. We are committed to the enterprise management philosophy [Integrity-based, constantly innovation, effective communication, quality services" and the goal of [Technical service customer", but also great attention to product design, manufacture, installation, adjustment. We will still try our best to maintain one-stop professional service.

Product Categories : Cnc Router Series > Woodworking Cnc Router